Damage Prevention

Don't ever assume you know where the underground utilities are located.

One of the greatest single challenges to safe pipeline operations is the accidental damage caused by excavation. In accordance with state and federal guidelines set forth by PHMSA, damage prevention programs have been established to prevent damage to pipelines from excavation activities, using non-mechanical or mechanical equipment or explosives to move earth, rock or other material below existing grade. Laws vary by state, but most require a call to 811 between 48 to 72 hours before you plan to dig. Your local One-Call Center will let you know if there are any buried utilities in the area, and the utility companies will be notified to identify and clearly mark the location of their lines at no cost to you.

- ALWAYS CALL 811 BEFORE YOU DIG.

- WAIT THE REQUIRED AMOUNT OF TIME.

- RESPECT THE MARKS.

- DIG WITH CARE.

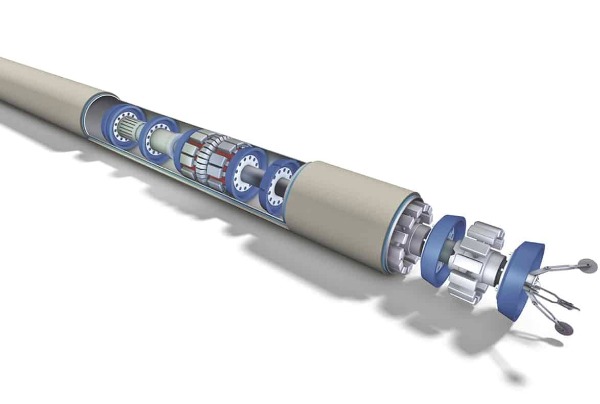

Pipelines are typically made of steel, covered with a protective coating and buried several feet underground. For your safety, markers are used to indicate the approximate location of pipelines. The markers contain the name of the pipeline operator, products transported and emergency contact information. Keep in mind that pipelines may not follow a straight line between markers, nor do markers indicate the exact location and depth of the pipeline.